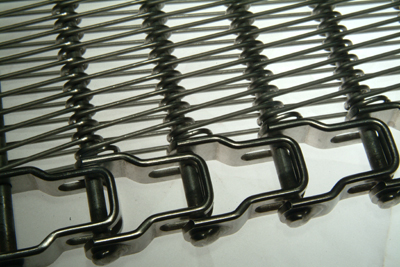

Belt Designs

A wide variety of belt designs are available to suit most applications. The belts depicted are available in diifferent pitches to suit your specific requirements.

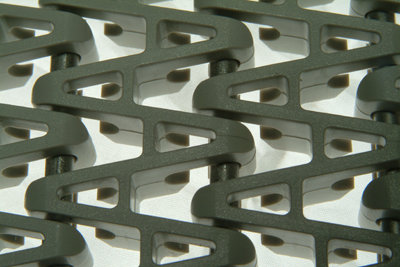

Omni Flex Belt

RELIABLE TURN CURVE AND SPIRAL PERFORMANCE

Originally developed from straight-running flat wire conveyor belts, Omni-Flex belts are spiral and turn curve metal belts that have been delivering consistent, dependable performance since 1959. Constructed with slotted pickets, Omni-Flex belts make right and left hand turns, as well as run straight.

STAINLESS STEEL, HEAVY DUTY CONSTRUCTION

All Omni-Flex components are precision crafted from premium quality stainless steel to exacting standards. The finish is smooth and burr free for easy clean-up and excellent sanitary and hygienic properties. Omni-Flex is constructed with heavy duty, precision formed rod ends for extended cage life and hot upset for maximum strength, reduced cage wear and abrasion. Two rows of reinforcing bar links are standard, providing the belt with ample strength.

BROAD RANGE OF SIZES AND ACCESSORIES

The flat wire mesh of Omni-Flex belts is available in three popular dimensions; 1" x 1", 1/2" x 1" and 1/3" x 1". Fatigue resistant pickets are available on most Omni-Flex belts and increase belt service life by approximately 30%. Other accessories such as guard edge plates, lane dividers and custom attachments are available for special needs.

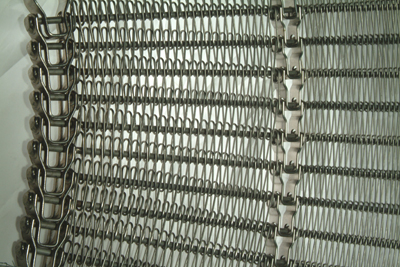

Omni-Grid

PROVEN RELIABILITY FOR SPIRAL FREEZING, COOLING & PROOFING APPLICATIONS

Introduced in 1965 and designed to satisfy the need for a lightweight, easy to clean spiral and turn curve conveyor belt, Omni-Grid stainless steel belts consist of an assembly of Wear Resistant Links and 6 gauge steel rods. Omni-Grid conveyor belts are available in 3/4" and 1" pitch and in widths of up to 40".

MULTIPLE OPTIONS FOR MAXIMUM CAPACITY

Primarily used in the food processing industry for freezing, cooling and proofing, Omni-Grid stainless steel belts can be manufactured with optional Omni-Tough wire mesh overlay (various mesh options available). Omni-Tough provides a significant improvement over conventional wire overlays by offering increased product support. High tensile strength steel construction also offers superior resistance to impact damage and deformation due to product sticking and freezing.

Special spirals (patented), used as guard edges, lane dividers and flights, can be added to any Omni-Tough overlay at the time of fabrication. These formed wire spirals are economical and efficient in operation, performing better than stamped metal partitions in most applications.

EXTENDED BELT LIFE AND SUPERIOR PERFORMANCE

Typically, initial wear and elongation (break-in) of a new metal conveyor belt is rapid, reducing the belt’s life span and requiring maintenance work to shorten the belt. To minimize these problems, Ashworth belting engineers designed the patented Wear Resistant Link, standard on all Omni-Grid belts. The unique “coining” feature on the Wear Resistant Link reduces elongation by nearly 50%. The coining feature also prevents the initial break-in wear between the rod and the link, reducing belt maintenance requirements and increasing belt life. The increased life of your new metal belt can be dedicated to conveying your product!

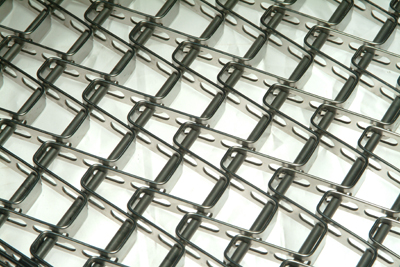

Omni-Lite

A Variation on our Omni-Grid® Line of All-Metal Conveyor Belts, Omni-Lite Features a Modular Plastic Conveying Surface for Excellent Product Release

Omni-Lite conveyor belting provides an easy release, low mass plastic conveying surface, while retaining the high strength of the stainless steel base belt. With a near perfect balance between product support and openness for good air flow, Omni-Lite is perfect for freezing and/or conveying small products.

REDUCED ENERGY CONSUMPTION

Unlike competing modular plastic conveyor belts, there is no massive amount of insulating plastic underneath your product to inhibit rapid freezing. The steel support structure of Omni-Lite provides extra strength and support to the belt, allowing less plastic to be used. This construction supports efficient energy use in your processing operation.

EXCELLENT PRODUCT SUPPORT

For soft products that require maximum product support, Omni-Lite provides extra surface area compared to regular Omni-Grid®.

IMPROVED AIR FLOW WITH INCREASED HYGIENE

Compared to most modular plastic conveyor belts, Omni-Lite has an open construction for good air flow and better cleanability. It’s easy to clean holes and slots, combined with an open surface structure, make Omni-Lite an exceptionally hygienic conveyor belt.

LESS MAINTENANCE

Omni-Lite is easy to repair and maintain. Any damaged High-Density Polyethylene (HDPE) plastic modules can be easily removed and replaced, without disassembly of the base belt. Downtime is reduced to minutes instead of hours, resulting in increased production and return on investment.

Omni Flex Belt

Omni-Grid

Omni Lite (Plastic) -- LIMITED TO 100 degF AND ABOVE